Description

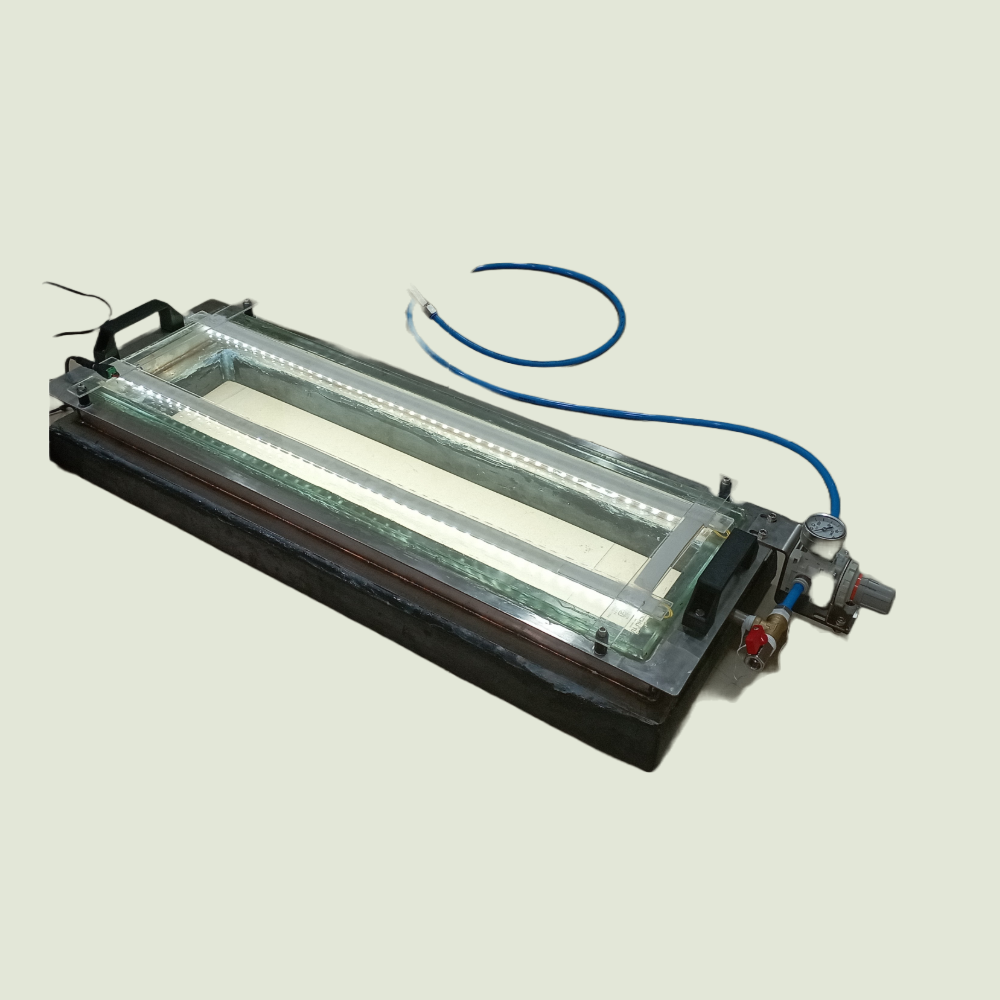

Bubble leak testing, or vacuum box testing, is a necessary part of a tank investigation process as suggested by API and other worldwide guidelines to lay out the state of a tank base plate weld or shell to base plate weld.

The design comprises a 750 mm weld inspection length, rugged SS316 body, calibrated vacuum gauge and vacuum regulator, LED light to ensure required brightness along the test weld.

FEATURES:

- Integrated LED light to maintain correct light brightness

- Higher visibility length 750 mm to improve productivity

- Factory Calibrated vacuum gauge and In-line vacuum regulator (NABL calibration on request)

- Increased efficiency

- Compact and portable Electric vacuum pump (optional)

- High & low vacuum variants

- Tank bottom and shell to bottom weld inspection models

Reviews

There are no reviews yet.